- Products

- Industrial Controls

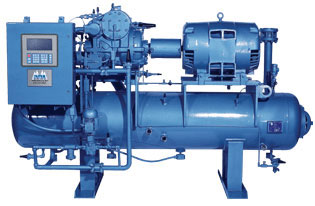

- Compressor Controls

- Screw Compressor Controls

Common Functionality and Features

These systems share a common set of functionality and features as follows:

- Common Scalable Hardware and Software Platform

- Real-Time, Easy-To-Read Animated Graphics Display

- Status and Diagnostic Screens Providing Continuously Updated Data on the Compressor’s Operating Conditions

- Extensive Alarm Reporting and Data Logging

- Data-Entry Screens For Control, Alarm and Failure Set Points Allowing Observation and Entry in the Processor’s Memory

- Comprehensive Set of Energy Management Features Including Set Point Scheduling, Ramp Start and Power-Fail Restart

- Built-In Open Communications Protocols Including Modbus RTU and Allen-Bradley DF1

- NEMA 4 Control Cabinet with Door-Mounted Keypad and Display

- Universal High Efficiency Power Supplies

- Microcontroller Main Processing Board

- Pre-Numbered Field Wiring Terminal Strip

- Battery with 10 Year Life to Ensure Data Retention During Power Interruption

- 16 Analog Sensor Inputs

- 4 Analog Control Outputs

- 64 Discrete I/O

Enhanced Control Functions

With the additional I/O provided, our compressor control systems can be designed to support the following additional equipment control solutions:

- Condenser Control

- Pump Package Control

- Evaporator Control

- Vessel Control

- Surge Drum Control

- As well as other multi-task functions as required