M&MRefrigeration, Inc.

Reciprocating Compressor Packages

Profile of Excellence

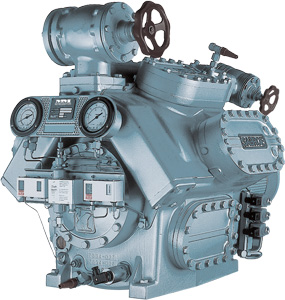

M&M Refrigeration/Sabroe reciprocating compressors are all heavy duty compressors designed for the toughest industrial and marine applications. Suitable for most refrigerants, including HCFC, HFC, hydrocarbons, ammonia, and carbon dioxide, they are well-proven, safe, and reliable. The basic design concept was introduced in 1954. All subsequent design improvements are compatible with early compressor models — a feature which ensures that older compressors can be upgraded to the latest design with improved efficiency.

This process of continuous research and development has resulted in a product line which is superior to any competitor in the market with regard to:

- Compressor range

- Flexibility

- Reliability

- Operating efficiency

- Environmental safety

- Operating safety

- Maintenance

Quality and Reliability In Each Step

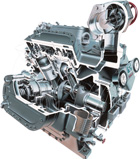

- Casing, covers, crankshaft, connecting rods, and cylinder liners manufactured at Sabroe’s own Meehanite foundries to ensure full process control

- Casing in grey cast iron quality GG25 (nodular ductile cast iron quality GGG50 for 580 psi high pressure compressors)

- Crankshaft in nodular ductile cast iron quality GGG70

- Design pressure: 370 psi for standard single and two stage compressors / 580 and 725 psi for high pressure compressors

- Compact modern industrial design with integrated suction and discharge manifolds

- Resistant to minor slugs of oil and refrigerants due to robust construction including spring loaded safety heads

- Oversized suction filters for protection of vital parts in the compressor

- Reliable lubrication ensured at all conditions through

- oversized connecting rod bearings and piston pin bearing

- efficient oil filtering

- internal gear-type oil pump for pressure lubrications of bearings

-

Reduced cylinder and piston wear

- cylinder liners with nitrited hardening of surface (Ni-temper)

- hard chromium piston rings

- lightweight pistons of special design and material

- Gas dampened discharge valves ensure long life

- Stop valves with non-rising spindle in stainless steel for long life and trouble-free operation

- External oil filter

- Water cooled heads removable without opening the refrigerant side of the compressor

Operating Efficiency and Safety

-

Easy operation due to the comprehensive standard equipment such as:

- suction and discharge stop valves

- electric immersion heater

- oil charging valve

- evacuating valve

- valve for prelubricating of bearings after a long standstill period

- oil level sight glass

- high, low, and oil pressure gauges

- High COP and excellent part load characteristics for reduced operating costs

- Automatic capacity regulation

- Fully unloaded start

- Guaranteed ratings according to ISO 916

- Low oil carry over due to highly efficient oil separation

- Oil separators are constructed according to current ASME codes

- Low noise and vibration level

- Internal by-pass valve to avoid excessive pressure

-

Safety switches to stop compressor in cases of excessive pressure and temperature, including:

- high and low pressure switch

- oil pressure differential switch

- discharge and oil temperature switch

- Asbestos free gaskets

- Balanced refrigerant tight shaft seal

- Low demand for spares

- Easy maintenance due to good accessibility

- Totally field repairable

These qualities have convinced our customers that M&M Refrigeration/Sabroe reciprocating compressors are second to none. For more information on Recriprocating Compressor from M&M Refrigeration, please contact one of our Sales Representatives.