M&MRefrigeration, Inc.

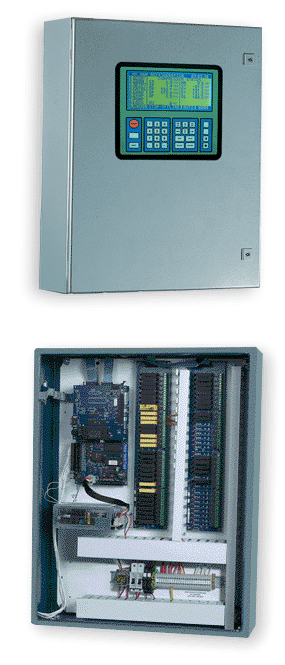

Microprocessor Control Panels

Control System Product Line

Our control system product line is different from all of our competitors in that it is scalable from equipment control, such as a screw or reciprocating compressor, to full plant control. One common scalable hardware and software solution does it all.

The M&M Refrigeration control system product line is comprised of three main product groups to meet the needs and budgets of any customer.

- Compressor Control Systems (CCS)

- “Off The Shelf” Control Systems (OTS)

- Engineered Control Systems (ECS)

Hardware Overview

Our microprocessor based scalable hardware platform is common across the entire M&M product line and provides the following standard features:

- Bright and easy-to-read displays

- A high degree of consistency in the user interface

- Stand-alone design which does not require a PC to operate

- Interchangeable parts from compressor to the plant control system panels

- Designed to support future expansion

- Designed-in backward compatibility

Common Hardware Features of Control System Product Line

- NEMA 4 or 4X panel

- Full numerical keypad

- Multiple sized backlit displays with graphics capability

- Support for up to 64 analog inputs

- Support for up to 16 analog outputs

- Support for up to 224 digital I/O

- Support for up to 4 communication ports

- High efficiency universal power supplies

- Battery back up memory

- Optional high speed modem

- Support for open communication protocols

(Allen Bradley DF1, Modbus RTU and BACnet)

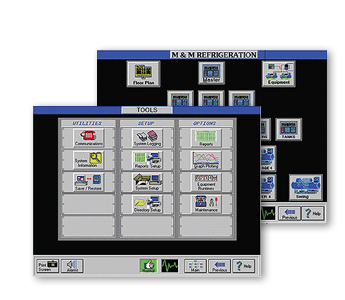

Software Overview

Our control system software is built around a core infrastructure providing the basis for everything we do. The way data is displayed, the navigation of screens, alarm processing and logging of data are all standard features in every microprocessor product we produce.

Every refrigeration control software function is designed to be easily adaptable to meet our customer’s needs. The list of software functions continues to grow with an ever-expanding set of standard features and options.

PC Software Features · M&M PC Monitor

This approach allows us to deliver products with a common look and feel, software that is fully tested, the ability to support all levels of facility complexities and provide a system to meet any budget size. Some of our software’s key features include:

- Standard infrastructure (displays, logs, alarm processing)

-

Standard software packages

- Screw compressor controllers to retrofit all major manufacturer’s units

- Reciprocating compressor controllers to retrofit all major manufacturer’s units

- “Off The Shelf” controllers such as evaporator panels, condenser panels, pump package panels and ice rink skid panels

- Stand alone controllers for ice machines, spirals, chillers, engine control, etc.

- Many options available in each module

-

What a user friendly interface should look like:

- Meaningful, readable displays with information organized by function, making the system easier to use

- Transfer of training — consistent user interface across all product lines including PC software; you only need to learn one system

- “At a Glance Technology” — data formatted and highlighted for quick reference by the operator

- Logs — extensive logging capability provides a very useful diagnostic tool for isolating system problems

- Alarms and failures — extensive alarms with names in user-friendly text